- Силиконовая стекловолоконная ткань с покрытием

- Сварка стекловолокна.

- Защитник из нейлонового рукава

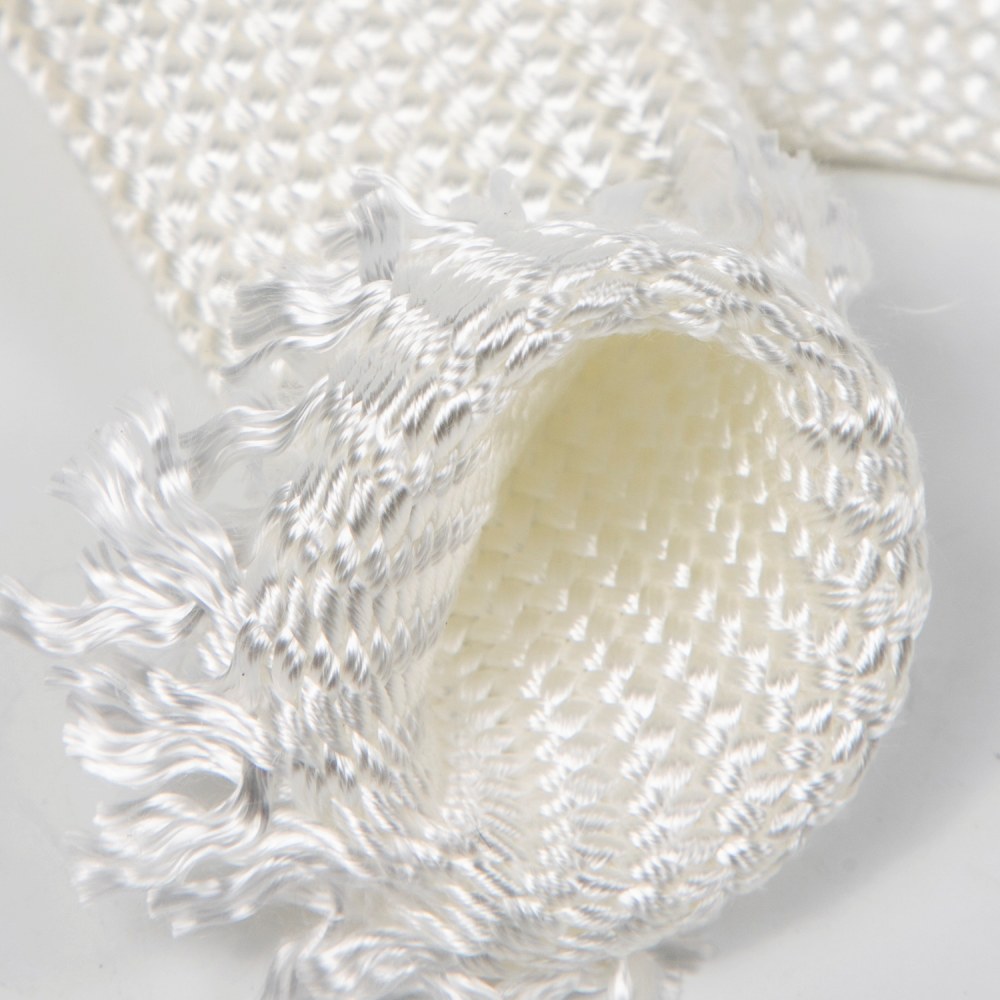

- Гидравлический шланговый рукав

- Нейлоновая защитная рукав для шланга

- Гидравлический шланг защитный огневой рукав

- огневой рукав для шланга

- защитный огневой рукав шланга

- керамическая лента волокна

- Игла из стекловолокна с алюминиевой фольгой

- NINGGUO BST THERMAL PRODUCTS CO., LTD.

- Отправить нам: vanessa-cheng@live.cn

- Позвони нам: +86 15856303740

Specated Ipv6 Network

Specated Ipv6 Network